Sveiki! Šodien es esmu ļoti priecīgs runāt ar jums par vides atmaskošanu un to, kāpēc mums vajadzētu rūpēties par savu vidi un to, kā tehnoloģija var palīdzēt mums rūpēties par savu vidi. Šodien mēs uzzināsim, kā mēs varam ražot nerūsējošo tēraudu videi draudzīgā veidā. Šajā rakstā mēs pievērsīsimies uzņēmumam, kas pazīstams ar nerūsējošā tērauda ražošanu; Pulda Metāls. Viņi atrod veidus, kā aizsargāt vidi, izmantojot jaunas tehnoloģijas un zaļo praksi, vienlaikus saglabājot spēju ražot augstākās kvalitātes produktus.

Inovatīva tehnoloģija nerūsējošā tērauda ražošanai:

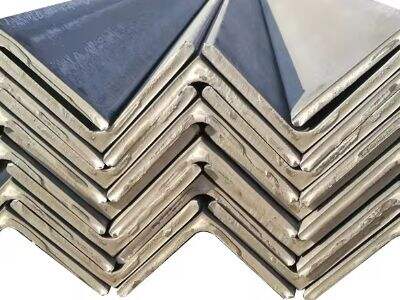

Pulda Metal ir anoti-anodizing ir viens no vadošajiem nosaukumiem nerūsējošā tērauda nozarē, kas ražo tēraudu, piemēram, nerūsējošā tērauda plakanais stienis. Vienmēr meklē jaunus, labākus veidus, kā uzlabot sava darba kvalitāti un strādāt drošāk mūsu Mātes Zemes labā. Viņi ir izstrādājuši īpašas sistēmas, kas savāc, piemēram, tērauda ražošanas procesā radīto siltumu. Un tā vietā, lai ļautu šim siltumam zaudēt, viņi to atgūst, tādējādi ietaupot daudz enerģijas. Tas ne tikai palīdz uzņēmumam ietaupīt naudu, bet arī samazina kaitīgo gāzu daudzumu gaisā, kas ir labāk ikvienam.

Īsumā par politiku: Sadarbība vides labā

Izrunātais Pulda Metal viens pats nevar darīt visu, lai palīdzētu videi. Tāpēc viņi ir nolēmuši sadarboties ar citiem uzņēmumiem, kas ražo nerūsējošo tēraudu, piemēram, stieņu metināšana nerūsējošais tērauds. Viņi ir iesaistījušies diskusijā savā starpā par idejām un plāniem atrast tīrāku, videi nekaitīgāku veidu nerūsējošā tērauda ražošanai. Šī grupa ir vērsta uz jaunu noteikumu izveidi, kas ļauj ikvienam uzņēmumam izmantot praksi, kas ir labāka mūsu planētai. Kopā tie var radīt lielāku ietekmi un palīdzēt parādīt pārējai nozarei ceļu.

MMC pastāv jau gandrīz 90 gadus. Nerūsējošais tērauds tika atklāts 20. gadsimta sākumā, taču to ražo domnas krāsnīs un elektriskās loka krāsnīs, kas ir ārkārtīgi izšķērdīgas.

Nozīmīga metode nerūsējošā tērauda ražošanas procesā radušos atkritumu samazināšanai ir Pulda Metal ūdens sistēma, kas nodrošina, ka jebkurš to izmantotais ūdens tiek pārstrādāts. Un tā vietā, lai izšķērdētu ūdeni, viņi attīra un atkārtoti izmanto ūdeni, kas palīdz uzturēt mūsu vietējos ūdens avotus tīrus un drošus.

Zaļās prakses izmantošana ar jaunākajām tehnoloģijām:

Pulda Metal uzskata, ka zaļa padarīšana ar jaunām tehnoloģijām ir labākais veids, kā palīdzēt uzturēt mūsu planētu. Piemēram, tie kausē metāllūžņus, izmantojot elektriskās loka krāsnis. Tie darbojas ar tādu pašu daudzumu tig nerūsējošais tērauds patērē daudz mazāk enerģijas, salīdzinot ar vecākām mašīnām.

Labāka nākotne ikvienam:

Uzņēmumā Pulda Metal mēs patiesi ticam, ka jaunas tehnoloģijas, sadarbība ar citiem uzņēmumiem un mūsu resursu apsvēršana var mūs virzīt uz labāku rītdienu. To darot, tie ne tikai palīdz mazināt piesārņojumu/samazina to, bet arī ietaupa naudu. Tas ir labvēlīgs videi, kā arī cilvēkiem, kuri ir atkarīgi no nerūsējošā tērauda izstrādājumiem.

Visbeidzot, veidojot lietas, ko izmantot ikdienas dzīvē, mums ir ļoti svarīgi, lai mūsu vide tiktu saglabāta. Tā ir nerūsējošā tērauda ražošanas nākotne, un Pulda Metal mums pierāda, ka mēs varam radīt nerūsējošo tēraudu tādā veidā, kas palīdz, nevis traucē mūsu planētai.